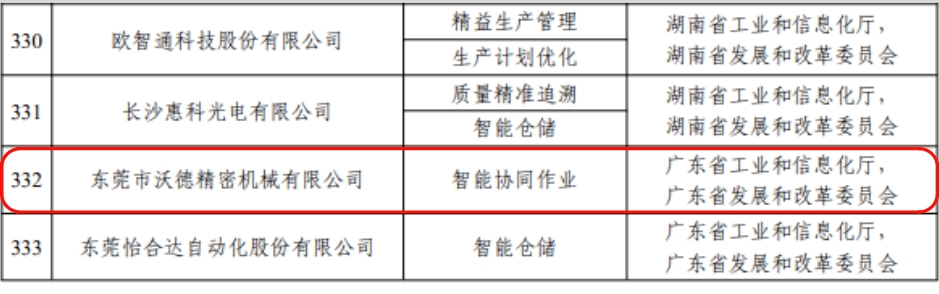

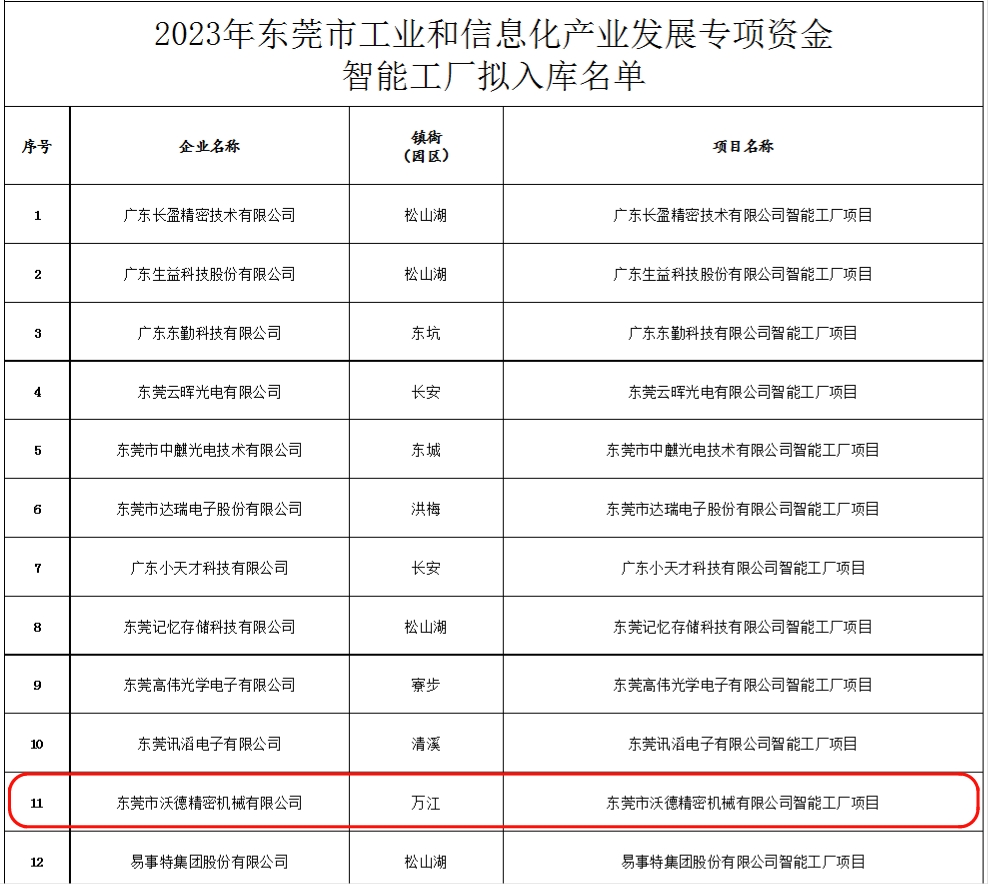

Recently, the Ministry of Industry and Information Technology of the People's Republic of China released the "Announcement of the List of Lists and Excellent Scenarios of Intelligent Manufacturing Demonstration Factories in 2023". The "Precision Parts Flexible Intelligent Manufacturing Collaborative Operation Scenario" applied by Dongguan World Precision Manufacture Co., Ltd. was successfully selected into the intelligent manufacturing industry list of excellent scenes for manufacturing demonstrations. At the same time, the smart factory built by World Precision was successfully selected into the list of Dongguan smart factory projects in 2023 and will receive special fund support from Dongguan City for informatization.

Excellent scenario: collaborative work in flexible intelligent manufacturing of precision parts

Scene description:

For the precision parts machining industry, World Precision has built an intelligent workshop. The intelligent workshop consists of 2-3 intelligent machining production lines. Each intelligent production line consists of a five-axis machining center (equipped with an in-machine online detection probe), an RGV trolley and an intelligent It consists of loading and unloading robots (including mobile rails), three-dimensional smart warehouses and other intelligent automation equipment. The workshop has deployed 5G networks, switches, servers, firewalls, smart signage and other digital software and hardware, and established a cloud platform and data center to collect, store and analyze various data during the production process. The workshop has introduced the MES management system as the core to build a production scheduling system (FSE), a flexible production line control system, a SAP system and other real-time control production site equipment, fully integrating production and manufacturing resources, opening up information islands, and realizing equipment automation and process standardization, production flexibility, process control, information integration, decision-making autonomy, improve quality, reduce costs and increase efficiency, and create a flexible and efficient digital factory.

Can be solved by:

1. Solve the problems of difficult, cumbersome processes and low efficiency in small-batch, multi-variety discrete manufacturing in the precision parts processing industry;

2. Solve the problems of difficult information collection and coordination involved in equipment, materials, environment, personnel, logistics and other factors in production;

3. Solve the problems of heavy workload and low efficiency in production scheduling;

4. Solve the problems of heavy production management workload, low efficiency, high cost and difficult traceability;

5. Solve the problems of extensive equipment management, low utilization rate, low degree of automation, and inability to collect data.