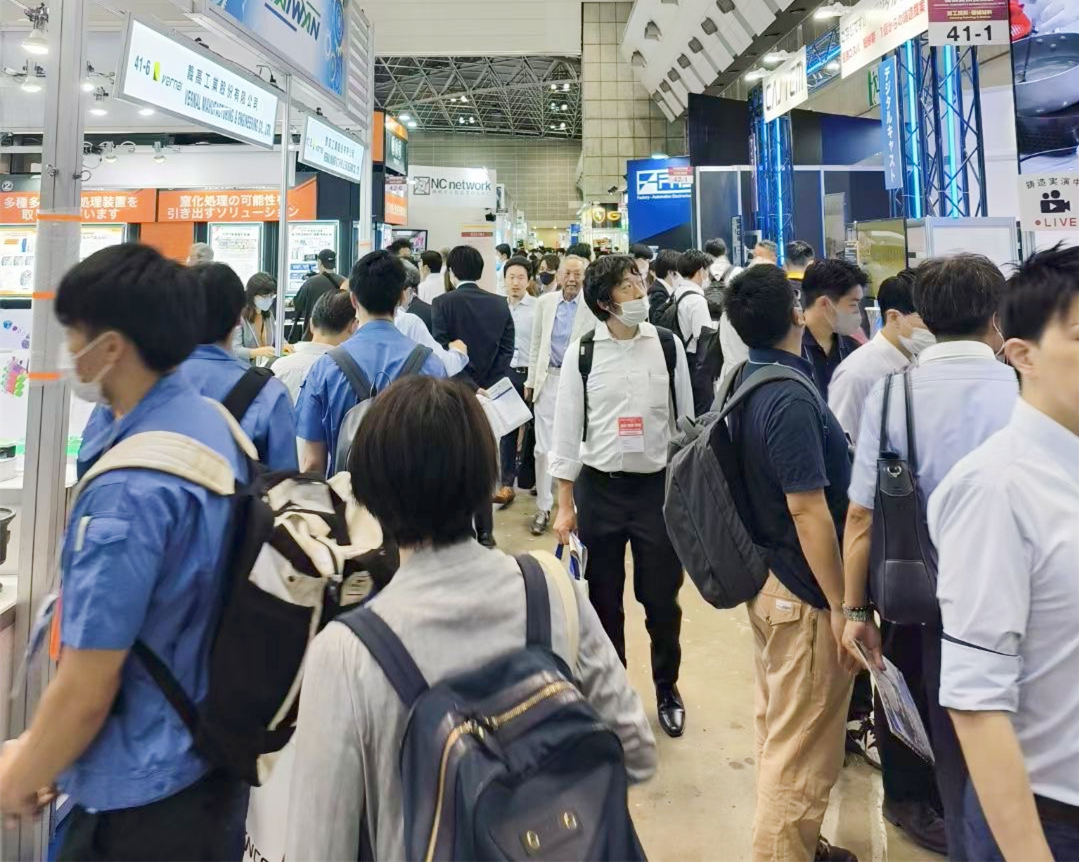

From June 21 to 23, the 2023 Tokyo Machinery Elements Exhibition was held at the Ariake International Exhibition Center in Tokyo

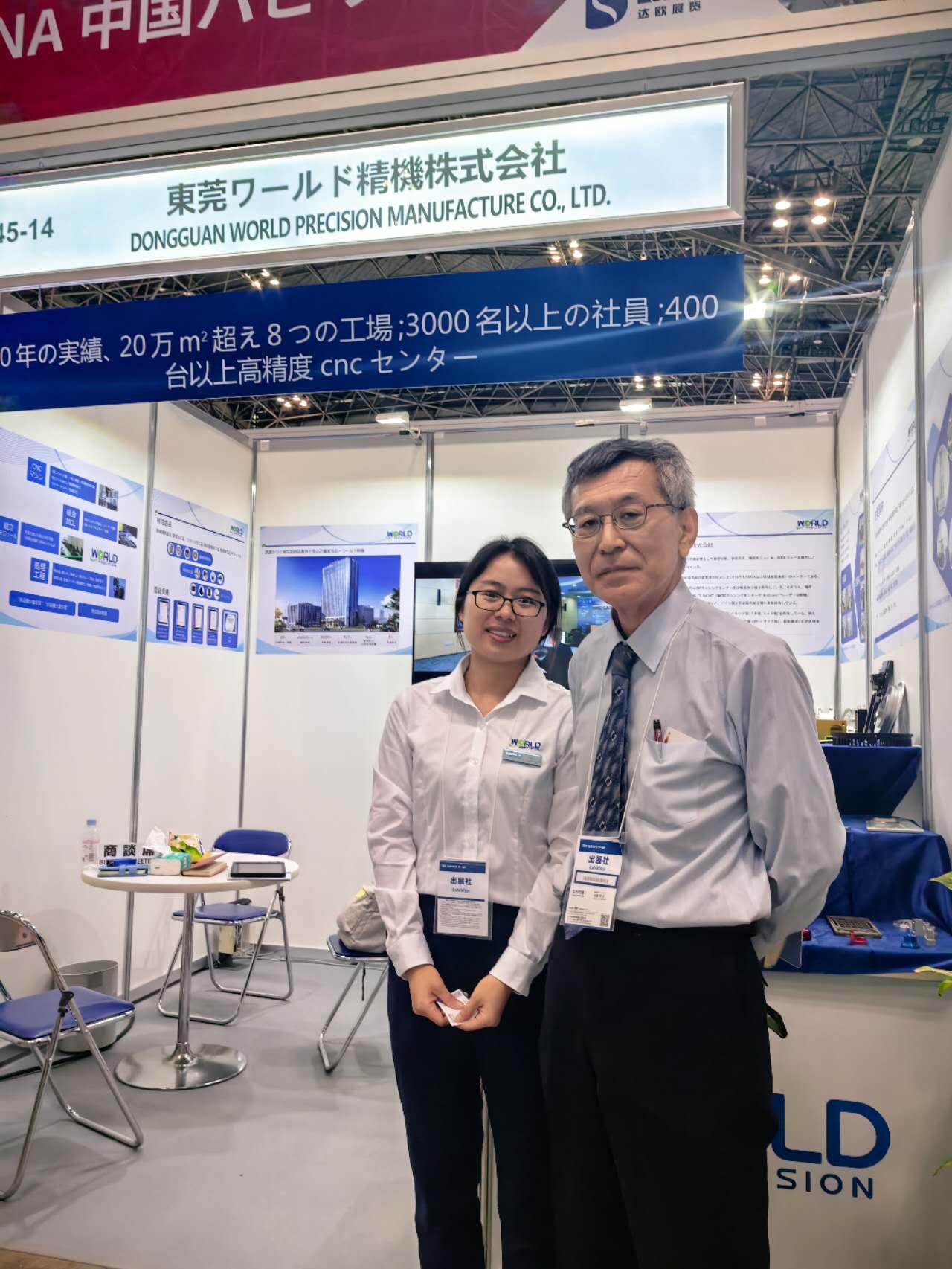

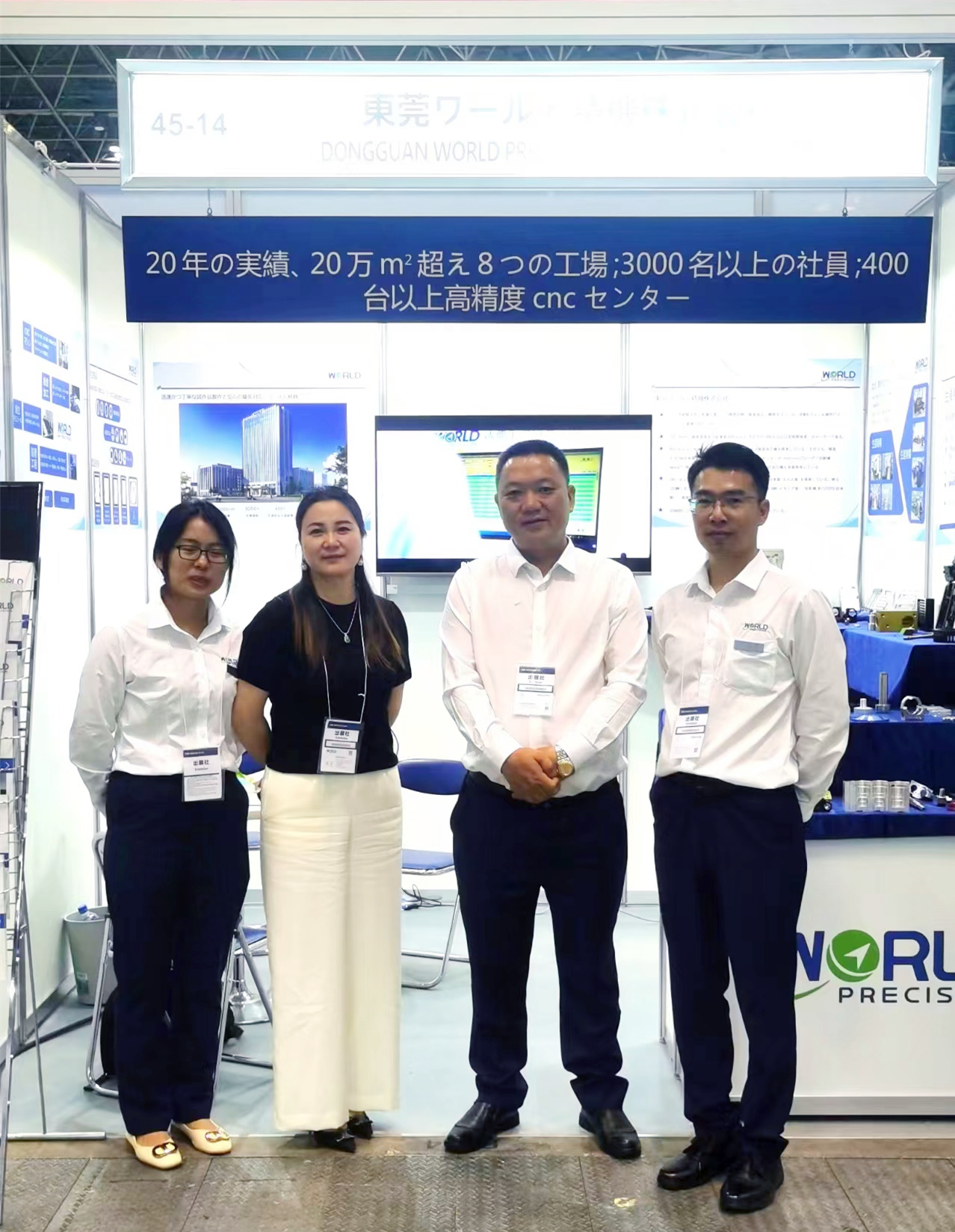

World Precision presented its full-process precision parts processing and assembly solutions at booth 45-14

Had a face-to-face communication with global customers and professional audiences

At the exhibition site , World Precision exhibited a series of exhibits such as precision parts, sheet metal parts, and modules, which demonstrated the precision and advanced machining and assembly capabilities of World Precision, and attracted many international customers to come to consult.

World Precision is committed to providing global customers with full-process precision parts processing and assembly solutions . After 20 years of experience accumulation and technology precipitation, World Precison has achieved high-quality leapfrog development, and has continued to cultivate in the main business fields such as precision parts processing, sheet metal processing, and module assembly.

World Precision introduced hundreds of high-end CNC machine tools from Germany and Japan , such as five-axis, vertical machining, horizontal machining, turning-milling compound, and centering machine , and can provide parts processing services mainly including precision turning, milling, and grinding. Up to ±2μm.

World Precision built its own sheet metal workshop and introduced high-end laser cutting machines, pipe cutting machines, bending machines, stamping forming and welding equipment to meet customer sheet metal processing needs

World Precison headquarters workshop can realize vacuum heat treatment processes such as quenching, annealing, normalizing, carburizing, nitriding, etc., and has many surface treatment capabilities such as anodizing, electroplating, electrolytic polishing, and passivation.

It can realize one-stop high-precision processing and surface treatment of the whole process of parts and components, and meet customers' customized needs of " multiple varieties and small batches" and "less varieties and large batches ".

In the future, World Precision will continue to adhere to the service tenet of " people-oriented, continuous innovation, high quality and speed, and customer first ", keep in mind the corporate mission, continue to catch up with the world's advanced level, and continue to move towards the vision of becoming a world-class precision machining solution provider .