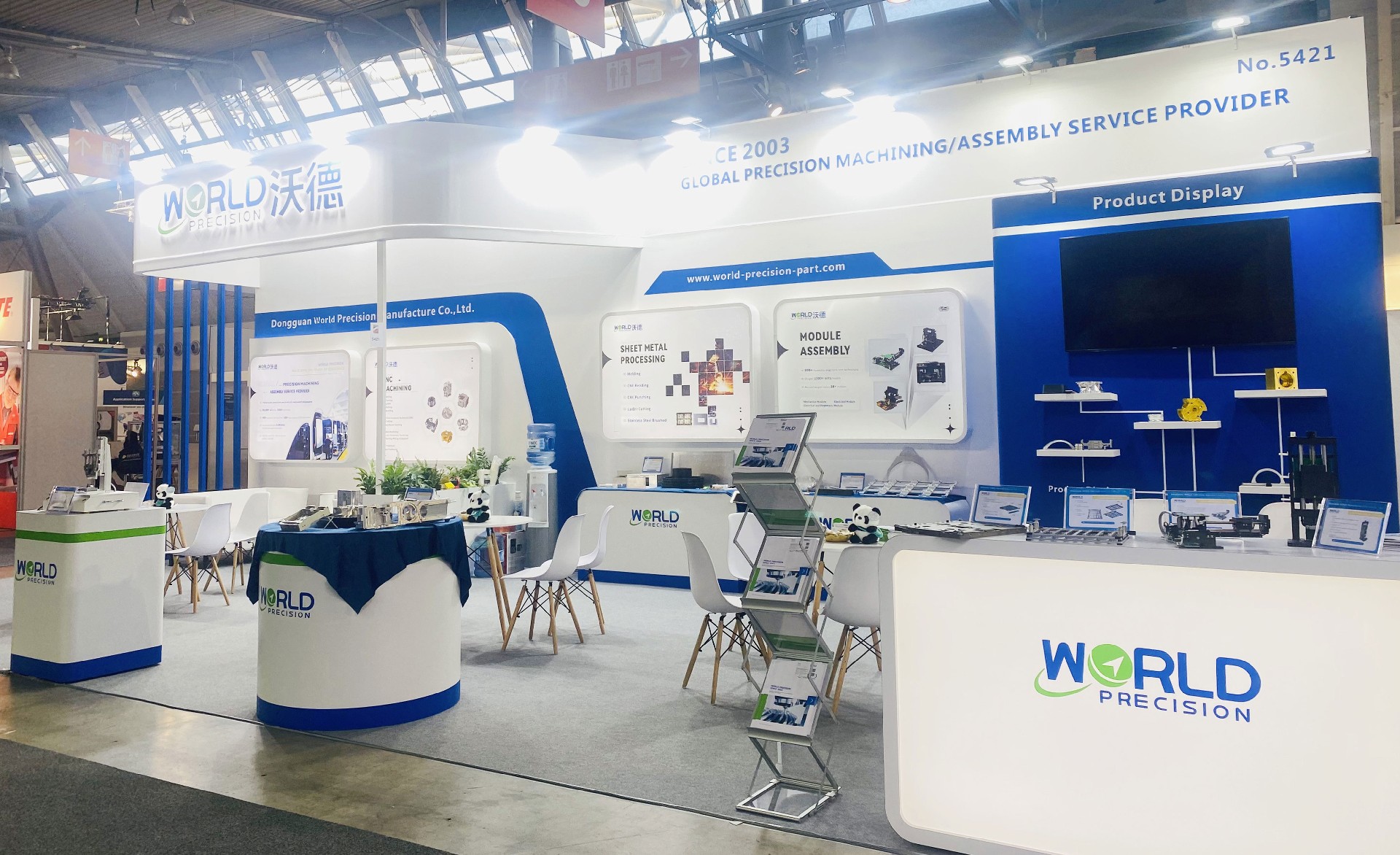

On October 10, the Motek 2023 kicked off at Landesmesse Stuttgart GmbH

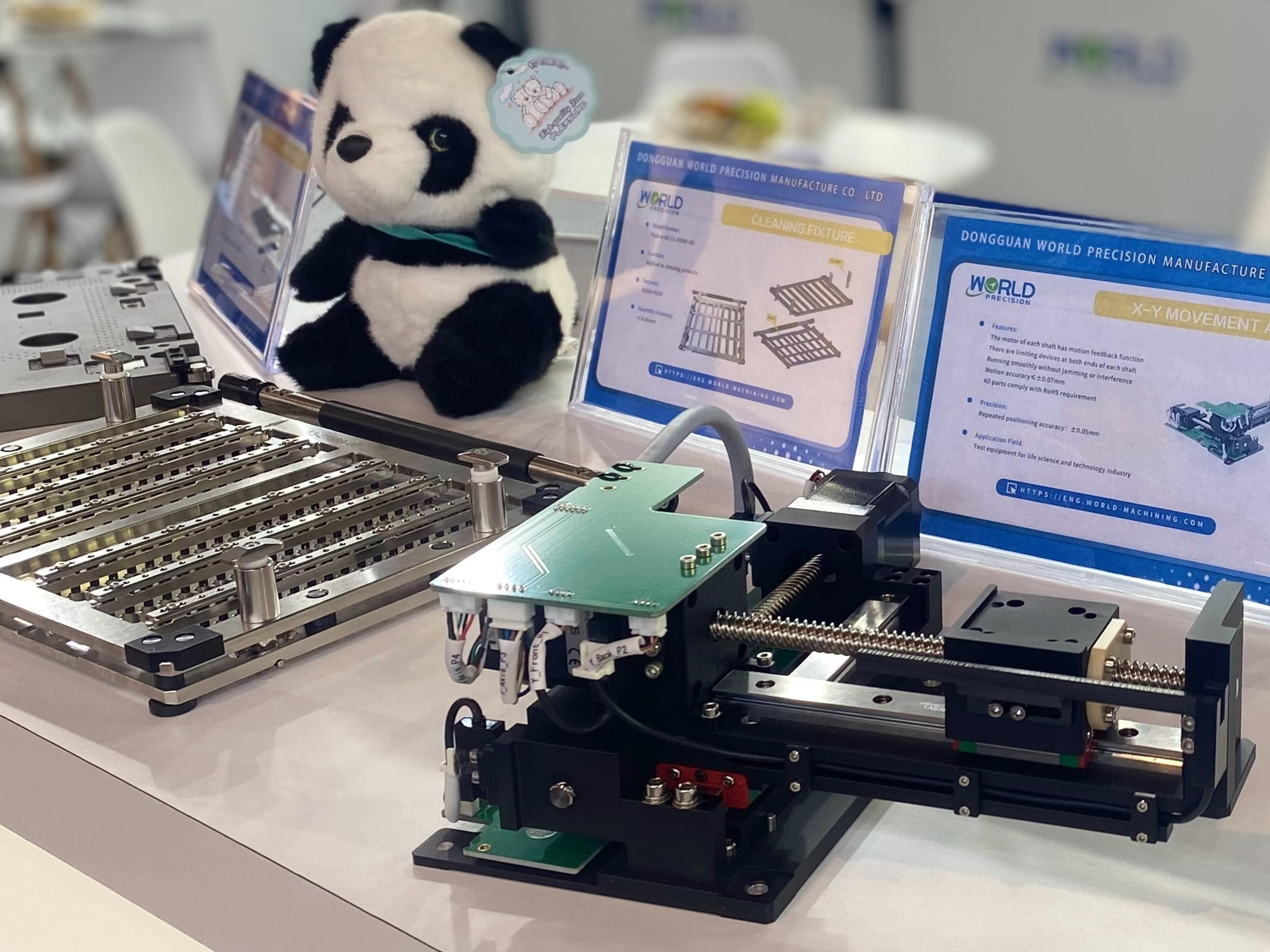

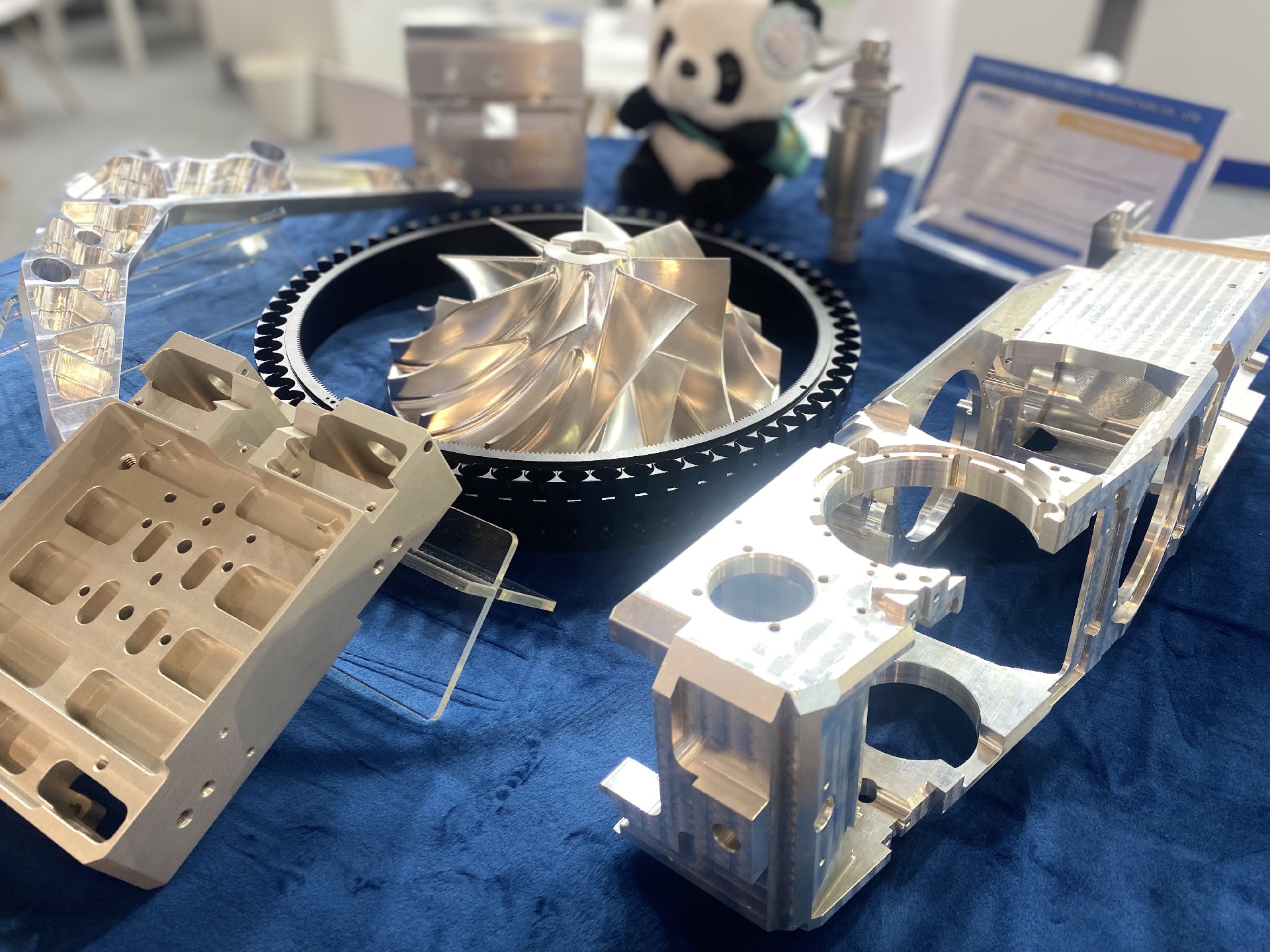

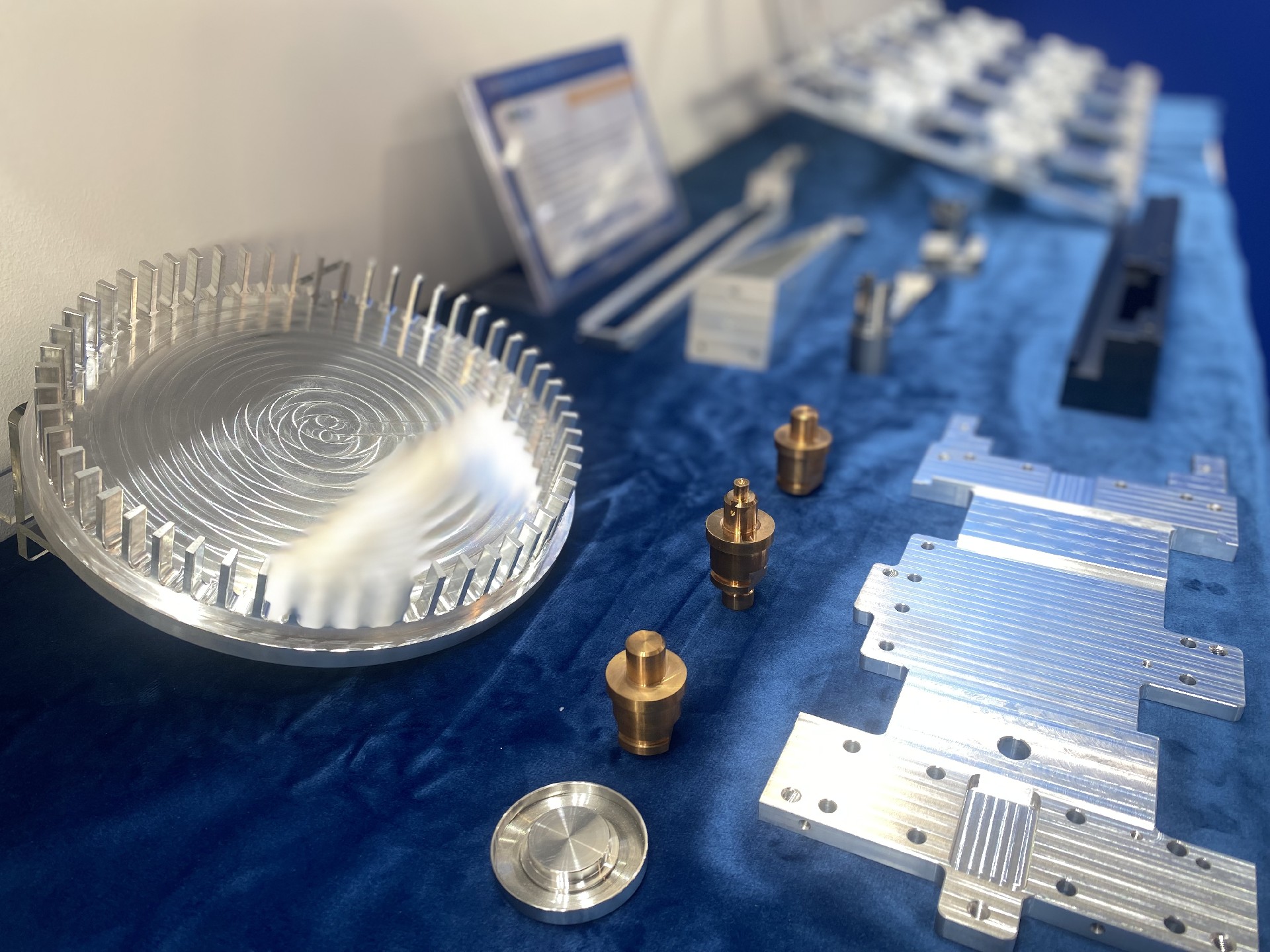

At the exhibition site, World Precision exhibited a series of precision components, sheet metal parts, modules

Demonstrating World Precision’s industry-leading machining and assembly capabilities

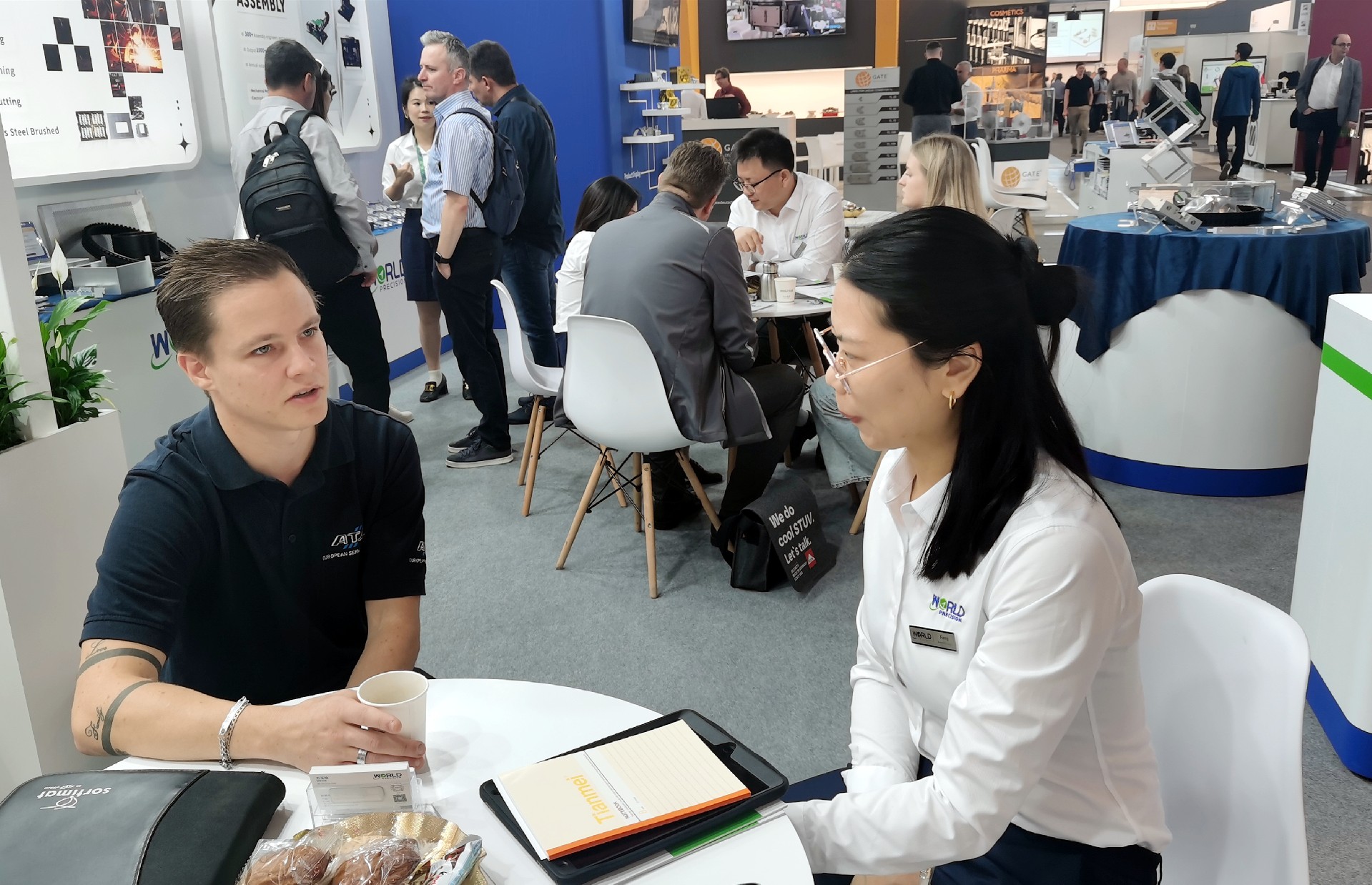

Attracting many international customers to come for consultation

△Module series World Precision is committed to providing full-process precision parts processing and assembly solutions to global customers After 20 years of experience accumulation and technology accumulation World Precision has achieved high-quality leap-forward development Continue to deepen our efforts in main business areas such as precision parts processing, sheet metal processing, and module assembly World Precision has introduced hundreds of high-end CNC machine tools from Germany and Japan, such as five-axis, vertical machining, horizontal machining, turning and milling composite and longitudinal lathes. It can provide precision milling, turning, grinding, wire cutting, and EDM processing services, the processing accuracy can reach ±2μm; World Precision built its own sheet metal workshop and introduced high-end laser cutting machines, pipe cutting machines, bending machines, stamping forming and welding equipment to meet customers' diverse sheet metal processing needs; World Precision has built its own precision module assembly workshop, and its products include linear modules, cross modules, bending modules, syringe modules, etc., with a batch manufacturing capacity of up to 1,000 sets per month. In addition, World Precision's headquarters has a heat treatment workshop that can realize quenching, annealing, normalizing, tempering, carburizing, quenching and tempering, ion nitriding and other vacuum heat treatment processes; World Precision's outsourcing workshop can perform anodizing, blackening, etc. on parts. A number of special surface treatment processes such as oxidation, electroplating, electropolishing, passivation, chromate treatment, etc.; World precision integrated parts and components, one-stop high-precision processing and surface treatment capabilities, can fully satisfy customers' "Low volume high mix" ” and “High volume” customization needs. Wonderful and exciting, not to be missed There are more surprises to share with you at the exhibition We are at Hall 5 Booth 5421 Looking forward to your visit